Articles / Case Studies

Hydrosil’s filtration media is highly efficient and cost-effective for eliminating pollutants. The team of experts at Hydrosil will work with you to identify the best possible solution with the highest quality products in a timely, professional and economical way. Read the case studies below to learn how we helped customers across a variety of industries solve their unique pollutant challenges.

Read our articles/case studies:

-

Crude Oil Spill

A crude oil pipeline ruptured causing numerous gallons of oil to leak into a nearby river. Crude oil contains petrochemical compounds that are harmful to the environment. These compounds include but are not limited to polycyclic aromatic hydrocarbons (PAHs), C19-C35, C9-C18, C5-C8, benzene, toluene, ethylbenzene, xylene (BTEX), and several volatile organic compounds.

Crude oil pipelines are typically used to route product from producers to refineries. Pipelines have strict regulations to follow to ensure the integrity of the pipes and safety to the community. With strict regulations in place to maintain the pipelines and identify when leaks are present—The US has seen a rapid decline in the amount of crude oil pipeline leaks.

Hydrosil was contracted to assist in remediating the surface water in the creek. Twelve large frac tanks were filled with contaminated water from the crude oil spill. The water contained oils, several long chain hydrocarbons, VOCs, and hazardous pollutants. The treatment train was designed by the consultant onsite to target the specific compounds that were identified in the water. The target flowrate was 500 gallons-per-minute (gpm).

The treatment train began with a dissolved air floatation (DAF). A DAF system is a treatment system for clarifying water using chemicals to separate suspended solids, metals, and particulate from water. The chemicals that are used in the DAF system are little to no concern for the HS-200 as the chemicals are added in small doses (typically on the lower spectrum between 5-7 ppm).

Following the DAF system was a series of pressure vessels containing HS-200 (Organoclay) 14×40 mesh. The HS-200 is Hydrosil’s pure organoclay that is designed to adsorb up to 75% its’ own weight in oil. The HS-200 was selected as a pretreatment to granular activated carbon to target the oils. Utilizing HS-200 as a pretreatment to activated carbon allows the activated carbon to target the smaller chain hydrocarbons such as BTEX, styrene, and other hydrocarbons. The influent data showed the inlet oil to the HS-200 had a concentration of 200 ppm, and at discharge from the HS-200 it was under 1 ppm. Hydrosil was on standby with an additional 128,000 pounds of HS-200 if large peaks of oil or other hydrocarbons would exhaust the media. However, no replacement of the HS-200 was necessary for the project. The spent HS-200 was disposed of in accordance with state and federal regulations. When the HS-200 was selected for the treatment train—Hydrosil already had the product in inventory and was ready to be loaded on a truck. This project was an emergency treatment job that posed challenges such as construction delays and incremental weather as this project took place during the winter months.

After three months of treating nearly fifty-five million gallons of water, Hydrosil’s HS-200 was successful in reducing high level concentrations of oils and petrochemical hydrocarbons including BTEX by achieving 99% reduction in concentrations.

Read More -

Condensate Oily Water Separator

An air compressor manufacturer uses Hydrosil’s Organoclay product in their product line as the oil water separator.

Hydrosil’s HS-200 Organoclay is used to treat the condensate that has oily compounds in the stream. The organoclay targets common lubricants such as polyalphaolefins (POAs), dieters polyalkylene glycols (PAGs), and polyglycols.

Read More -

Air Filtration for Air Compressor

Maintaining a healthy air compressor starts with treating the air that the compressor uses. In order to treat this air facilities will install air intake filters packed with activated carbon (HS-AC) or custom blend to treat specific contaminates of concern such as potassium permanganate (HS-600).

Air Intake Filters are positioned at the entrance to where atmospheric air is brought into the compressor. The air intake filters generally start with a particulate filter that will treat large particulate such as dust, pollen, and large debris. Behind this pre filter, an adsorption filter or gas phase filter is in place to clean the air of unwanted vapors, hazardous gases, and unwanted fumes.

Gas phase filtration is an invisible threat that cause millions of dollars in damages every year. To avoid the cost of replacing corroded computers/servers, compressors, and downtime due to malfunctioning equipment—it is vital to ensure corrosive gases are oxidized and made harmless using adsorption or gas phase filtration.

Read More -

PCBs Dewatering Project

An environmental service company was dewatering water a construction site that contained high levels of polychlorinated biphenyls (PCBs), metals, and semivolatiles. The flowrate of the system was 500 gpm.

Hydrosil was contracted to supply the filtration media for the dewatering project. The project utilized HS-250-ACR to treat the wide range of contaminates for 5 months. Results of the project are shown below.

Pollutant Influent Effluent Reporting Limit Metals (mg/L) Chromium 0.01 <0.001 N/A Nickel 0.04 <0.001 0.0082 Zinc 0.002 <0.001 0.066 PCB (ug/L) PCB-1016 <0.24 <0.05 0.24 PCB-1221 0.8 <0.05 PCB-1248 1.1 <0.05 PCB-1260 <0.24 <0.05 PCB-1262 0.3 <0.05 PCB-1268 <0.24 <0.05 Semivolatiles (ug/L) Benzo(a)anthracene 0.22 0.008 0.04 Benzo(a)pyrene 0.24 <0.05 0.05 Benzo(k)fluoranthene 0.26 <0.05 0.05 Chrysene 0.32 0.006 0.05 Dibenz(a,h)anthracene 0.07 <0.005 0.02 Hexachlorobenzene 0.52 <0.001 0.05

Read More -

Phosphorus Dewatering Project

An environmental service company was contracted to treat the contaminated groundwater from a construction site. The water contained 304 ug/L of phosphorus with a reporting limit of 10 ug/L and permit limit of 0.05 mg/L.

Hydrosil was contacted for an inquiry on the HS-300 which would remove phosphorus. The contractor completing the service work ran testing on the HS-300 and the contaminated water which resulted in concentrations that were non-detect.

Following testing, the system was put into service at a flowrate of the system was 300 gpm with 13-minute empty bed contact time.

Pollutant Influent (ug/L) Post HS-300 Treatment (ug/L) Reporting Limit (ug/L) Phosphorus 304 4.2 10

Read More -

One Stop Shop

How To Find the Right Treatment Solution

History repeats itself. When Hydrosil is approached about finding the right solution the first question we ask is what is the application?

The manufacturing process or chemical processes involved in the application have A LOT to do with the type of water chemistry. A few common problems Hydrosil sees from project to project include:

Landfills: Arsenic, Metals, Petrochemical Hydrocarbons, TCE, Benzene

Paper and Pulp: Chlorinated Compounds, Total Suspended Solids (TSS), Phenol, Resin Acids,

Food Industry: Chemical Oxygen Demand (COD), Biological Oxygen Demand (BOD), Fats, Oils and Greases

Refineries or Mines: Heavy Metals, Oils, Petrochemical Hydrocarbons, BTEX

Now don’t get me wrong—don’t look at your source of contaminated water and think those are the only problems you will encounter! Every project is different and the water across the country is different everywhere.

At Hydrosil we take the time to learn about your application and help you select the right filter media or custom blend for your treatment train. Hydrosil is your one stop shop to treat the full range of pollutants in your contaminated water, because we know there will be more than one pollutant to treat.

Read More -

Antimony in Water

Antimony (Sb) is naturally occurring in small quantities in water. Drinking water standards for antimony is 6 ppb. High levels of antimony are commonly found near coal burning and petroleum refineries, fire retardants, ceramics, and electronic manufacturers. EPA recommends treating antinomy with coagulation/physical filtration and reverse osmosis. Hydrosil recently worked with a company on treating high levels of anatomy and they tried both treating the contaminated water with ferric chloride and pumping and treating it with HS-250-AC. See results below to understand how well HS-250-AC works when treating antimony.

Raw Water 5 ppm Ferric Chloride 10 ppm Ferric Chloride 20 ppm Ferric Chloride HS-250-AC Antimony, Total (mg/L) 0.155 0.145 0.142 0.139 0.02

Read More -

Landfill Leachate Treatment

A landfill leachate pond measuring at a pH of 7 had high antimony concentrations that were over the discharge limit of 0.07 mg/L. The contaminated water also contained high levels of arsenic, iron, magnesium, manganese, and silica.

Hydrosil was contacted to evaluate the project and lower the levels of antimony and any other compounds. Hydrosil suggested two products for the application: HS-250-AC and HS-AS. Resin was used in the middle of the train per the suggestion of the landfill owner. The bench scale testing was completed at 10 minutes EBCT with a flowrate of 0.16 gpm. The bed volumes utilized were 0.063 ft3. After the study was completed, the system was installed in the field at 5 gpm in 55-gallon drums. The results for the system are shown in the table below.

TREATMENT TRAIN Influent (mg/L) Post HS-250-AC (mg/L) Post IX (mg/L) Post HS-AS (mg/L) Alkalinity (as CaCO3) 1750 1800 1460 603 Hardness (as CaCO3) 1100 1000 1000 280 Antimony, Total 0.155 0.020 0.020 0.020 Arsenic, Total 0.971 0.584 0.554 0.532 Iron, Total 11.1 0.435 0.4 0.4 Magnesium, Total 101 83.8 81.0 44.7 Manganese, Total 0.964 0.585 0.105 0.0374 Silica, Dissolved 25.4 28.1 7.8 0.18 pH 6.82 7.36 7.23 7.13 Temperature (°C) 25.8 21.4 20.8 20.5 Dissolved Oxygen (mg/L) 0.059 1.7 4.6 7.1

Read More -

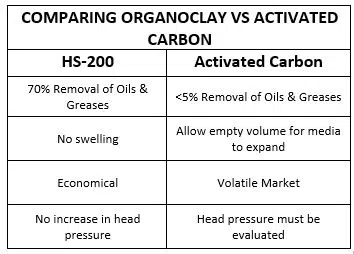

Oil Treatment HS-200 vs GAC

HS-200, also known as organoclay is primarily used in the petrochemical industry for treatment of oils, greases, and hydrocarbons. Hydrosil’s HS-200 attracts these compounds using its’ impregnated active ingredient.

Many mistake the use of activated carbon to treat oils and greases, but this is not the most cost-effective solution for this application. Activated carbon’s pore structure is not designed for large compounds such as oils. Oils, greases, and select hydrocarbons will block the pores which result in lowering the efficiency of activated carbon.

Applications of oil treatment using the HS-200: Spill Remediation, Refineries, Off-Shore Platform, Oil, Gas, & Petrochemical Industries, Industrial and Commercial

Read More -

Chlorine Gas RMP

𝐖𝐡𝐚𝐭 𝐢𝐬 𝐲𝐨𝐮𝐫 𝐑𝐌𝐏?

Chlorine gas is a listed hazardous air pollutant. In accordance with US EPA the use of chlorine over 2,500 lbs is subject to a Risk Management Plan (RMP). RMP will require an emergency response procedure and steps you have taken to prevent an accident.

If you don’t have a plan in place releasing only 10 lbs of chlorine will require you to report your incident to the National Response Center (NRC)– Which in the end may cost you millions of dollars in fines.𝐖𝐡𝐚𝐭 𝐜𝐚𝐧 𝐲𝐨𝐮𝐫 𝐑𝐌𝐏 𝐛𝐞?

Hydrosil’s HS-Cl is designed for these types of emergencies.For more information on RMP regulated substances and RMP program requirements:

Read More -

VC Monomer Removal in Exhaust

A resin manufacturer was discharging an air stream from a mixing tank. They were experiencing high levels of vinyl chloride monomer 1 ppm during normal conditions and 300 ppm during upset conditions.

Hydrosil suggested an air filtration unit that could handle the 4,000 cfm of vinyl chloride contaminated air they were moving from the tank. The system had two passes of 3″ bed depth of HS-600. Hydrosil’s HS-600 is designed to target the VC monomer. For more information on the chemistry of HS-600 and vinyl chloride monomer click the link here: Reaction For Removal of Vinyl Chloride Using Potassium Permanganate | HS-600 | Hydrosil International (hydrosilintl.com)

Industry Type: Resin Manufacturer

Pollutants: Vinyl Chloride

Media Used: HS-600

Read More -

PFAS Removal Lab Study

Lab Results

Hydrosil has experience using our proprietary organoclay, HS-PF, in combination with HS-ACC in pilot studies and in a laboratory setting. The results below are shown for a laboratory study using the media in combination in series.

Compound Influent (ug/L) HS-PF (ug/L) HS-ACC (ug/L) Efficacy (%) PFPeA 1.19 0.0352 0.0015 99.9 PFHxA 2.43 0.02 0.001 100.0 PFHpA 0.405 0.02 0.0013 99.7 PFOA 0.463 0.005 0.001 99.8 PFNA 0.0337 0.005 0.001 97.0 PFBS 2.94 0.334 0.001 100.0 PFPeS 0.984 0.005 0.001 99.9 PFHxS 2.36 0.0093 0.001 100.0 PFHpS 0.0777 0.0093 0.001 98.7 PFOS 2.02 0.014 0.0015 99.9 FOSA 0.03 0.005 0.001 96.7

Read More -

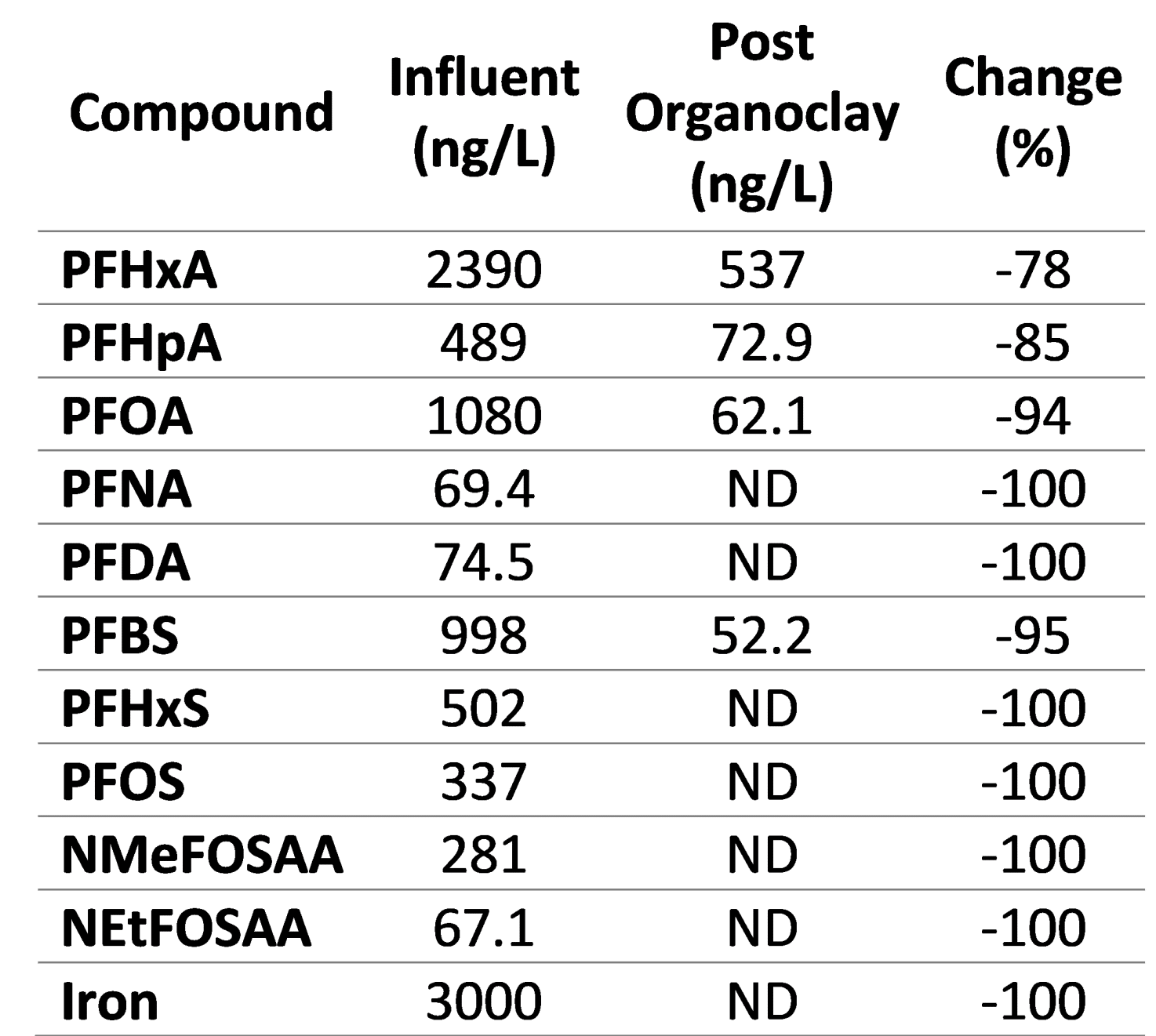

PFAS Landfill Contamination

Hydrosil was contacted to evaluate treatment methods for contaminated landfill leachate which showed high levels of PFAS and PFOA compounds. The concentrations of the contaminates were above the Wisconsin Groundwater Quality Public Health Enforcement Standard for PFOA. Initially the leachate was treated with four different medias one of which being HS-PF. The HS-PF showed the highest removal rates ranging from 78–100% removal, as shown below. The pilot study was completed at 5 gpm.

Hydrosil’s HS-PF is designed to remove per- and polyfluoroalkyl substances (PFAS). The media is an economical and efficient remediation process which removes both long and short chain compounds. Contact a Hydrosil representative to discuss an application today.

Read More -

Cu Removal in Groundwater

Contaminated groundwater was being treated using an air stripper, bag filters, and granular activated carbon. The system was initially designed to remove trichloroethylene (TCE) by the air stripper and remaining 10 ug/L was being taken up by the granular activated carbon (GAC). The system was not removing all the constituents necessary such as copper. The system was treating the water at 50 gallons per minute, and a concentration of copper < 5 ug/L. Occasionally the copper was spiking to 20 ug/L; Therefore, another step in treatment needed to be taken.

Hydrosil recommended the HS-MT. The HS-MT is 50/50 blend of HS-200 and modified earth. The blend has a high capacity for copper and some of the other constituents such lead and zinc that were found in the groundwater. The groundwater was successfully remediated with a vessel filled with HS-MT followed by HS-AC to remove the pollutants in a timely and economical way.

Industry Type: Industrial

Pollutants: Copper, Zinc, Lead, Trichloroethylene

Read More -

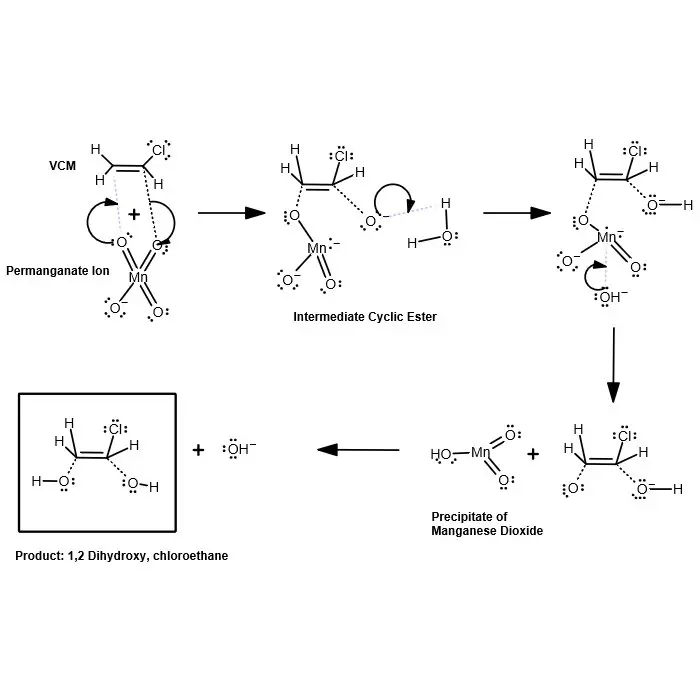

Reaction For Removal of Vinyl Chloride Using Potassium Permanganate

The reaction of the permanganate ion with vinyl chloride monomer is outlined in the figure above. The reaction produces 1,2 dihydroxy, chloroethane, an addition product, and a precipitate of manganese dioxide. A short description of the reaction is also included below. The typical oxidation reaction for an alkene by permanganate ion may be found in any general organic chemistry text.

The oxidation of an alkene leads to the formation of a compound with hydroxyl groups on the carbon atoms that were involved in the double bond, a 1,2 diol. Manganese (VII) in permanganate ion is ultimately reduced to manganese (IV) in manganaese dioxide. The carbon atoms of the double bond are oxidized. Even if no base is added at first, the solution becomes progressively more basic as the reaction proceeds.

In this oxidation reaction, the two hydroxyl groups become attached to the same face of the double bonds. The permanganate ion is believed to add to the double bond to give a cyclic intermediate a manganate ester. The first step of this reaction is the syn (same side) addition of permanganate ion to the double bond. This intermediate breaks down in the presence of water to give the cis-1,2 diol. Thus, there are no appreciable quantities of chlorine gas or formaldehyde formed in the reaction.

Read More -

Air Filtration Basics

The ideal air filtration system does not include only one type of air filter. An ideal air purifying system includes multiple filter technologies in order to capture the full range of pollutants in your air stream. The most common types of air filters are media filled filters/carbon filters, HEPA filters, particulate filters/pre-filters, air ionization, and UV.

Media Filled Filters are filters packed with highly absorbents for removing chemical fumes, gases, and other VOCs. The absorbents also referred to as “media” may either be activated carbon or altered media such as impregnated zeolite. These types of filters will capture the pollutants and will not release them until thermally or chemically altered. After all the active ingredient or unoccupied pores are taken up– the media must be replaced.

Read more about Hydrosil’s Air Filter Media.

HEPA filters will remove the smallest particle sizes, less than 0.3 microns in diameter, which is why they are commonly used in clean rooms and hospitals. All filters have a MERV (Minimum Efficiency Reporting Value) rating. A HEPA filter is rated in the highest group as shown below. The MERV rating is ANSI/ASHRAE Standard 52.2 with ratings between one (1) and twenty (20).

MERV Rating Particle Size Ranges Typical Filter Type 1-4 > 10.0 um Metal, Synthetic, Disposable Panel Fiberglass 5-8 3.0-10.0 um Media Panel Filters 9-12 1.0-3.0 um Rigid Cell, Cartridge V-Cells 13-16 0.30-1.0 um Rigid Cell, Cartridge V-Cells 17-20 < 0.30 HEPA & ULPA HEPA filters work well at targeting dust, pollen, pet dander, and other allergens. HEPA filters are commonly used in combination with media filled filters to remove both ultra-small particles and vapors and odors.

Air Ionization works by negatively charging particles and causing them to collect on a charged plate. This type of filtration has been known to produce trace amounts of ozone and is not effective at removing smoke and odors.

Ultraviolet (UV) is effective at removing viruses, bacteria, mold. This technology can be used in combination with media filled filters to remove odors, vapors, and chemicals which cannot be removed with UV.

Installing or Retrofitting Air Filtration System

If you are looking at changing an existing system or installing a new one there are a few things to consider:

- How many air changes per hour do you need?

- What is the design and actual air flow?

- What odors or vapors do you notice?

- Do you notice corrosion on capital equipment?

Air filters are essential in providing protection for capital equipment. All air handling units such as fans need protection from corrosive gases and particulate build-up.

Read More -

Remaining Service Life

The key to successful air filtration is replacing the media prior to having any issues such as corrosion, hazardous vapors, or foul odors.

Hydrosil can help keep your system in healthy service by testing your gas phase media in your filter. If the media is not changed out when need your system will function improperly. The percentage of available permanganate and the density of the gas phase media can be correlated to the active service life left in the product. If the media in the adsorber is Hydrosil HS-600 or an activated alumina based product, the following schedule can be followed:

HS-600

(% by Weight Active Chemical)Activated Alumina

(% by Weight Active Chemical)2.2 to 6.0 Safe 2.6 to 8.0 1.6 to 2.2 Borderline 1.9 to 2.6 1.2 to 1.6 Change 1.4 to 1.9 0.0 to 1.2 Change Immediately 0.0 to 1.4 The comments mean the following:

Safe— Reanalyze in 90 days

Borderline— Change in 30-90 days

Change— Change in 30 days, breakthrough could occur quickly under plant “spill” conditions

Change Immediately— Change Immediately

Read More -

Jar Test For Water Pollutants

The purpose of this test is to determine if the pollutants have any removal with a media. To conduct this test you will need approximately 2 liters of the polluted solution, one glass container and Hydrosil removal media.

Conduct tests to determine the pollutants present and concentrations on the polluted water. This is done as a base line. Place the Hydrosil media into the glass container and rinse the media with tap water 4 times. This allows the media to be hydrated and flushed of small particles. Once the media has been drained pour in the polluted water to the top portion of the media, do not fill the container past the level of the media. Let the polluted water/media remain in contact for 15 minutes. Pour out the media and test for presence and concentrations of the pollutants.

If the media was able to remove the pollutants with a 15 minute contact time. The media should work to remove the pollutants in your system.

The media and water should be disposed of accordance with local, state and federal laws.

Read More -

Groundwater Pollution: Sources & Solutions

Groundwater is an essential natural resource for drinking water, food, industrial processes, and recharging lakes, rivers, and wetlands. Groundwater is found under the Earth’s surface in rocks, soils, cracks and pores. Nearly 99% of the U.S. rural population uses groundwater as a source of drinking water. Contaminated groundwater is nearly always caused by man-made products such as paints, disinfectants, solvents, and gasoline. There are four major ways groundwater is contaminated.

1. Surface Contamination: Surface water such as rivers and ponds slowly infiltrate groundwater through the soil. If the surface water has contaminates, the contaminates will leach into the soil. Eventually hazardous pollutants will reach the aquifer and create a toxic industrial waste plume.

Agriculture: Chemicals such as pesticides and fertilizers can have a lasting effect on crop production, wildlife, and drinking water. The chemicals that are commonly used at golf courses or large farms will stay in the ground for years. Rainfall will dilute the chemicals; However, they will also help the chemicals to penetrate deeper into the ground reaching the aquifer.

Industrial: Surface impoundments and chemical spills/releases are typical at industrial facilities. It is not uncommon for above storage tanks to spill or leak. This is why it is important to have adequate barriers in place to protect against spills running into soil or corroded sewer systems. Surface impoundments at petrochemical facilities often contain hazardous wastes that if they are not lined correctly can leak to surface waters and soil nearby.

Mining: Industrial activities such as mining and metallurgy will lead to metal contamination in waterways such as lead, cadmium, and chromium. There are four types of mining impacts: Acid Rock Drainage, Heavy Metal Contamination & Leaching, Processing Chemicals, and Erosion and Sedimentation.

Natural Sources: Naturally occurring substances such as sulfates, iron, fluorides, and arsenic are found in water. The types and concentrations of natural impurities depends on water temperature, air temperature, pH, dissolved oxygen, flow conditions, and numerous others.

2. Subsurface Contamination: Groundwater contamination can occur from buried sources such as septic systems leaky sewers.

Underground Equipment: Equipment such as underground storage tanks (USTs) and piping can have toxic leaking chemicals and corrosion seep into the ground.

3. Landfill & Waste Disposal: There are municipal and industrial waste landfills that have different regulations on what can be disposed in them. Many times, chemicals that should be disposed of in hazardous waste landfills are not and contaminate municipal landfills.

Landfills: Typically landfills have a barrier (clay liner) between garbage and the ground which the landfill is built into or on. However, this barrier has been known to crack allowing the garbage containing contaminates such as battery acid, paint, and other cleaners to leak into the ground. The leachate from the chemicals are often considered to be hazardous mixtures that will pollute the groundwater.

Waste Disposal: Hazardous waste shall be disposed of by a licensed hazardous waste handler.

4. Atmospheric Contamination: Also known as atmospheric deposition is when water becomes contaminated due to air pollution.

Acid Rain: When nitrogen oxides and sulfur dioxide react in the atmosphere they create acids. These acidic compounds can take the form of rain, sleet, hail, snow, or dust. The effects of acid rain affects forests and plants, wildlife, surface waters, and humans.

Damaging effects of groundwater pollution vary from health issues, economic impact, and devastating changes to our ecosystem. Through proper regulations, filtration systems, management of disposing materials, and maintenance of equipment we can work to reduce negative impact on groundwater contamination.

Solutions for Contaminants Found in Groundwater:

Contaminant Source Potential Hydrosil Remediation Ammonia Agriculture, Industrial Activities, Naturally HS-100 Arsenic Mining, Naturally, Industrial Activities HS-AS Cadmium Mining, Industrial Activities HS-MT Chloride Drinking Water, Industrial Activities HS-AC Chromium Mining, Industrial Activities HS-MT Color Industrial Activities, Naturally HS-AC Copper Mining, Industrial Activities HS-MT Cyanide Agriculture, Industrial Activities HS-300 Fluoride Naturally, Industrial Activities HS-F Fats/Oils/Greases (FOG) Industrial Activities HS-200 Iron Naturally, Industrial Applications HS-200 Lead Naturally, Industrial Applications HS-MT Nickel Naturally, Industrial Applications HS-MT Nitrate Naturally, Agriculture, Industrial Activities HS-300 Sulfate Naturally, Agriculture, Industrial Activities HS-300 Thallium Naturally, Industrial Applications HS-MT Volatile Organic Compounds (VOC) Industrial Applications, Agriculture HS-AC , HS-600 Zinc Naturally, Industrial Applications HS-MT

Read More -

RO Membrane Protection

What Happened:

Packaged reverse osmosis (RO) systems are commonly used across industry for wastewater treatment. RO systems/skids remove bacteria, salts, total dissolved solids, heavy metals, and various harmful chemicals from water. There are several parameters that should be monitored to identify fouling of a RO membrane. These parameters include silt density index, the pressure drop across the system, permeate flowrate, and percent rejection (TDS rejected by RO system). RO system manufacturers will often use a pretreatment system to reduce the amount of oily substances and harmful pollutants.

How Hydrosil Helped:

For pretreatment, Hydrosil typically provides HS-200 Organoclay Series to RO skid manufacturers to remove damaging pollutants. Hydrosil suggests that for properly configurating an RO system a complete cation and anion analysis of the water should be completed.

Industry Type: Industrial Water Treatment

Pollutants: Heavy Metals, Salts, Cations, Anions

Media Used: HS-300, HS-200 Organoclay Series

Read More -

PFAS/PFOA Limits

A state agency was enforcing per- and polyfluoroalkyl substance (PFAS and PFOS) discharge limits of 400 ug/L. To meet this limit, the state was working with an environmental remediation service company to come up with a solution so groundwater could be discharged. The groundwater contained 1,600 ug/L of PFAS and 32 ug/L of PFOA.

Hydrosil suggested the HS-PF followed by HS-AC. The remediation company implemented these medias in series which resulted in a reduction of pollutants below 44 ng/L. The HS-PF cleaned up remaining metals and total aliphatic hydrocarbons (TAH) as well as PFAS. The HS-PF is an economical solution which does the heavy lifting. HS-PF followed by an activated carbon or resin makes an efficient and cost effective remediation system.

Industry Type: Groundwater

Pollutants: PFAS, PFOA, TAH, Metals

Read More -

Airport Fumes

Airports have plenty of sources of pollution: pushback trucks, food trucks, cleaning crew vehicles, baggage carts, buses, restaurants, jet engines, and bathrooms. Not only are the odors created by these pollutants, but some are dangerous to human health. The unburned hydrocarbons created from jet engine exhaust can easily be brought into the terminals where passengers await their flights. HS-AC filters installed in air handling systems at airports scrub out diesel odors, jet fumes, restaurant odors, and other VOCs and odors created from day-to-day activities at the airport.

Hydrosil has supplied airports across the country with gas phase filters for their air handling units. Due to the cost of disposing/regenerating media, Hydrosil has offered its’ dump and refill services. Hydrosil’s dump and refill services will remove the spent filtration media, dispose of it, and refill the filter with new filtration media.

Industry Type: Airport

Pollutants: Polycyclic aromatic hydrocarbons (PAH), VOC, HAP, Odors

Media Used: HS-AC

Read More -

Odors at Science Museum

Visitors at a museum were complaining of cooking and garbage odors. The museum had an air handling unit that was bringing in fresh air from outside that was located over the museums’ restaurant.

Hydrosil was contacted to help solve the odor issues the museum was experiencing since the restaurant started up. The employee at the museum who handled all the maintenance work took pictures of the current air handling and sent them to Hydrosil. Hydrosil identified that the system had air filters, but only particulate and that there was just enough space for a gas phase filter. Hydrosil provided the museum with a honeycomb filter filled with HS-AC-P.

Industry Type: Museum

Pollutants: Cooking and Garbage Odors, City Odors

Media Used: HS-AC-P

Read More -

Animal Clinic Odors

Animal clinics bring in all kinds of different creatures. When the liver is not functioning correctly such as an infection or disease high levels of ammonia may be created in urine. This ammonia will result in a pungent and unpleasant odor. Other odors that are commonly found at animal clinics which are used for disinfecting the space are aldehydes and/or ketones.

Hydrosil has worked with animal clinics on various air filtration projects. The animal clinics have installed separate passes or blends of HS-AC-P-PO and HS-600 in air handling units. The HS-AC-P-PO is effective at removing ammonia and ketones as the HS-600 will oxidize the formaldehyde, acetaldehyde, benzaldehyde, and tolualdehyde which are commonly found at veterinary offices.

Industry Type: Animal Service

Pollutants: Ammonia, aldehydes, ketones

Media Used: HS-AC-P-PO, HS-600

Read More -

Chlorine Emergency Scrubber

Chlorine is a common gas used in industry. Accidental release of chlorine gas can cause health risks as well as regulatory risks. A scrubber manufacturer works closely with Hydrosil for various toxic gas scrubber systems.

Hydrosil manufacturers HS-CL for chlorine removal on the chlorine gas storage units. The scrubber manufacturer has tested the HS-CL and demonstrates that Hydrosil’s media has 98% removal efficiency.

Industry Type: Manufacturing

Pollutants: Chlorine

Media Used: HS-CL

Read More -

Pilot System for Refinery

A refinery was having new waste-water discharge limits coming into place. Over the years the refinery had maintained compliance below the new limits majority of the time; However, occasionally the waste-water would have spikes of hydrocarbons up to 25 ppm. The refinery contacted an environmental service company to put together a system which would ensure they would always operate in compliance.

The environmental service company contacted Hydrosil to implement the HS-250-AC in the system to remove the hydrocarbons to less than 1 ppm. The system designed consisted of a particulate filter and the HS-250-AC. The system is being used as the permanent modification until the facility can modify the process to improve water discharge concentrations.

Industry Type: Refinery

Pollutants: Hydrocarbon, particulate, oil

Media Used: HS-250-AC

Read More -

Gulf Oil Spill Disaster

An oil rig in the Gulf of Mexico leaked an estimated 3 million barrels of oil. Environmental contractors were frantically evaluating options to remediating the oil spill.

Hydrosil supplied HS-200 to the environmental remediation contractor working on the cleanup of the oil spill. The environmental remediation contractor initially performed bench-scale testing, and from there designed a treatment system using the HS-200. The treatment system effectively remediated millions of gallons of contaminated water.

Industry Type: Oil and Gas

Pollutants: Oil, hydrocarbons, heavy metals

Media Used: HS-200 Organoclay Series

Read More -

Increasing Analyzer Run Time

A plant had a flue gas desulfurization (FGD) unit to remove sulfur dioxide from the flue gas before being discharged to the environment. The environmental group at the facility had continuous emission monitoring systems (CEMS) located near the point of discharge measuring various pollutants in flue gas stream. The facility was noticing issues with ammonia reacting with sulfur dioxide in the CEMS which would than produce an ammonium salt. The salt was causing significant down time of the analyzer.

Hydrosil provided the facility with HS-100-PO to install in the CEMS inlet scrubbers. The HS-100-PO is an ammonia scrubbing media that will remove the ammonia before reacting, cooling, and forming salt.

Industry Type: Chemical Plant

Pollutants: Ammonia, Ammonium Salt

Media Used: HS-100-PO

Read More -

Rotten Egg Odors

Refineries are known for having high concentrations of sulfur in their waste streams. A refinery located near the Appalachian Mountains had exhaust vents on a system that discharged high concentrations of total reduced sulfur (TRS) and hydrogen sulfide (H2S). Although the facility was incompliance majority of the time—the vents would detect spiked concentrations of H2S up 0.5 ppb. Not only were these concentrations unsafe for workers, but the facility was receiving complaints from nearby residents regarding the rotten egg/cooked cabbage odors due to the TRS.

Hydrosil suggested a custom blend which included HS-600 and HS-AC-P-HS 0.3g/cc. This blend would remove both the unsafe H2S and odorous TRS (sulfur dioxide and methyl mercaptans) that were being vented to the atmosphere.

Industry Type: Oil Refinery

Pollutants: H2S, SO2, Methyl Mercaptans, TRS

Media Used: HS-AC-P-HS 0.3g/cc, HS-600

Read More -

VC Plume Cleanup via SVE

A consulting company was working on a soil vapor extraction (SVE) system which was remediating vinyl chloride (VC). SVE is a physical treatment for removing volatile compounds from soil. The vapor is extracted from underground and brought to the surface to be remediated. The surface treatment for the volatile gases can range from activated carbon, thermal deconstruction, or impregnated media. The type of treatment depends upon the volatile gas that is being treated.

Vinyl chloride (VC) is a highly volatile compound and can effectively be removed by SVE. Hydrosil provided the consulting company the HS-600. The HS-600 effectively removes the VC to nondetectable levels.

Industry Type: Consulting

Pollutants: Vinyl Chloride

Media Used: HS-600

Read More -

Shutdowns for Skunky Smells

The smell of marijuana is a growing concern across Canada and the U.S. The pungent aroma of harvesting cannabis is causing major complaints by residents which law enforcement is cracking down on. One of the largest growing facilities in the U.S was ordered to shut down due to the amounts of complaints by local residents.

Hydrosil has provided HS-Cannablend-Select to customers (industry use and filter manufacturers) to help keep facilities in compliance. The HS-Cannablend-Select is utilized in filters to capture the odors that cannabis gives off (terpenes and teraponids). The terpenes that are detectable by nose are limonene and pinene. Hydrosil provides the HS-Cannablend-Select which has been proven to drastically reduce these odors to nondetectable levels.

Industry Type: Cannabis Grow House

Pollutants: Teraponids, Terpenes (Limonene, Pinene), Fertilizer VOCs

Media Used: HS-Cannablend-Select

Read More -

Coolant Filtration

Coolants are commonly used in automotive and HVAC applications. This particular client was an automotive manufacturer and had several different chemicals/coolants that were leaking into the wastewater system.

Hydrosil suggested the HS-250-ACR to clean up the coolants and other hydrocarbons in the wastewater stream.

Industry Type: Automotive Manufacturer

Pollutants: Hydrocarbons, Coolant, Oils, Grease

Media Used: HS-250-ACR

Read More -

Food Processing Plant with High Ammonia

A plant was running an evaporator train, and by the time the vapors were at the final condenser the vapor contained a significant amount of ammonia. After the condenser, the liquid was cooled in a pond and discharged from the facility. The facility was failing to comply with the state regulations due to the high ammonia in the stream.

Hydrosil suggested the facility install a pump and treat system utilizing HS-100 prior to discharging the high ammonia stream into the nearby river.

Industry Type: Food Processing Facility

Pollutants: Ammonia

Media Used: HS-100

Read More -

Construction Workers Concerned of Toxic Fumes

A construction site was experiencing high levels of methyl methacrylate used in a polymer that was used in concrete. The construction site was also seeing levels of volatile organic compounds (VOCs) and hazardous air pollutants (HAPs). The construction site setup air handling units around the construction site to purify the air and make it a safe working environment. They were using activated carbon, but were not seeing a significant change in methyl methacrylate concentrations.

Hydrosil suggested running some tests using a variety of medias (HS-600, XB-17, and HS-AC-P-KOH). After testing the client had seen significant consumption of the media and a reduction in methyl methacrylate concentrations.

Industry Type: Construction Site

Pollutants: Methyl methacrylate, VOCs, HAPs

Media Used: HS-600, HS-AC-P-KOH

Read More -

Semiconductor Plant

During fabrication, semiconductor manufacturing sources emit several volatile organic compounds (VOCs) and hazardous air pollutants.

Hydrosil suggested a custom blend to remove harmful acid gases and VOCs. One location that Hydrosil works with loads the media into HS-400 modules. The facility pulls samples from the air filtration system and sends them back to Hydrosil to test once per quarter.

Industry Type: Semiconductor Fabrication

Pollutants: Ammonia and Acid Gases

Read More -

Contaminated Stormwater Runoff

A facility was out of compliance due to the treatment equipment being obsolete. The facility was struggling to stay in compliance with the state regulations for heavy metals, biochemical oxygen demand (BOD), and total suspended solids (TSS) among other constituents.

A contactor used Hydrosil’s media to initially complete an in-house and in-field pilot test. The testing with the contaminated water was proven to be successful. The contractor then implemented the HS-200 Organoclay Series and HS-AC in two separate mobile skids which successfully treated the water.

Industry Type: Industrial Stormwater Runoff

Pollutants: Heavy Metals, Hydrocarbons, Organics, BOD, COD, PCB, and TSS

Media Used: HS-200 Organoclay Series, HS-AC Water, HS-ACR

Read More -

Economical Remediation for Manufacturing Facility

A medium sized manufacturer located in western Michigan was visited by the local sanitary district inspectors. The purpose of the visit was to locate the source(s) of contamination that upset their biological treatment system. It was discovered that their compressor condensate contained approximately 35% by volume of free oil. Even though the amount of contaminated water was not enough to have caused the upset, it triggered enough concern that the inspector locked out the discharge source. The highly concentrated oily water was a significant cause of elevated levels of BOD, COD and oil and grease in the discharge water. The facility was advised to remediate the situation immediately or face a total shut down of their manufacturing.

The problem was quickly solved by placing Hydrosil’s HS-200 Condensate Remediation Paks at every compressor condensate discharge. The Paks were chosen for their ease of installation and low maintenance requirements.

Industry Type: Metals Manufacturing

Pollutants: Oily Condensate, BOD, COD, grease

Media Used: HS-200

Read More -

PFAS treatment at Air Force Base

Polyfluoroalkyl substances (PFAS) are a group of man-made chemicals that includes PFOA, PFOS, and many other chemicals. PFAS is used in a variety of industries around the globe and are a growing environmental concern. Hydrosil has worked with several clients around the U.S. on this emerging contaminant. This particulate client working with an air force base was required by state to meet a discharge limit of 70 ppt. The client was currently at a concentration of 250 ppb and did not know how to reduce the concentration using an economical method.

Hydrosil suggested the HS-PF which resulted in approximately 90% removal of the PFAS. Hydrosil then suggested running the system through a HS-ACC bed for a polish. The client was satisfied with the cost of the project and met the enforced state regulations on PFAS. The HS-PF is an economical solution which does the heavy lifting. HS-PF followed by an activated carbon or resin makes an efficient and cost effective remediation system.

Industry Type: Air Force Base

Pollutants: PFAS

Media Used: HS-PF and HS-ACC

Read More -

Bears with French Fry Problem

A ski resort located up in the Rocky Mountains was experiencing a bear problem near the outside kitchen vents. The vent was located above the French fry fryer and was routing the greasy vapors outside to attract the bears.

Hydrosil provided filters filled with XB-17 in the existing air handling system. The media inside the filters in replaced once a year and has kept the bears from the ski resorts kitchen.

Industry Type: Air Force Base

Pollutants: Greasy Odors

Media Used: XB-17

Read More -

Art Museum with Foul Odors

An art museum in downtown Chicago was experiencing foul odors in the art gallery. These odors/compounds can be damaging on the paintings and structures. The museum needed a gas phase filter in order tot take care of odors.

Hydrosil provided air filters filled with XB-17 to the art museum which were installed in the existing air handlers. Hydrosil supplied HS-18 modules for an air handling unit which resulted in a low pressure drop. The odors were removed and the paintings were protected from the damaging odors/compounds.

Industry Type: Art Museum

Pollutants: City Odors

Media Used: XB-17

Read More -

Arsenic Removal in Groundwater from Landfill

A landfill was leaching off arsenic at a concentration of 0.254 mg/L at 30 gpm. They were looking for a removal efficiency of 22.5%.

Hydrosil suggested a particulate filter followed by the HS-AS which would have the ability to remove 99.5% of the arsenic in the stream. The client proceeded with Hydrosil’s recommendation and cleaned up the arsenic leachate above the expected removal efficiency.

Industry Type: Landfill

Pollutants: Arsenic

Media Used: HS-AS

Read More -

Discharge Limit Challenges for Small Business

Without connection to sewer lines, three fabricators are presented with challenges in processing manufacturing discharge. These fabricators are required to have discharge limits for oil and grease of no more than 5 PPM before discharging to surface water. To alleviate the challenges brought by not having sewer lines, HS-200 was added to their process. The fabricators each pressure wash tubing to remove light oil. Once the facility cleans the finished products, the water passes through a 10-micron filter bag, followed by a drum of HS-200 at 1/4 gpm. The concentration of the inflow is 30-50 PPM oil and grease. After the introduction of HS-200 into the process, the outflow meets discharge standards and the filtration vessels lasting about a year provide the fabricator with a long-term cost-efficient solution.

Read More -

Combatting Heavy Metals in Wastewater

About the Project:

A metal plating company uses rust preventative in a cleaning bath resulting in a wastewater that contains suspended solids of 10-20 parts-per-million (ppm) oil, heavy metals, calcium and magnesium. The treatment system runs at 36 gallons per minute (gpm) and consists of a sand filter, bag filters, and ion exchange resin tank with a mixed bed resin, and an reverse osmosis (RO) system. The plating company’s system was not cost efficient and required weekly maintenance. Every day the company spent $60 on bag filters. The resin had to be regenerated every week and both the resin tanks and RO membranes had to be cleaned every week.

To make the system more efficient, the sand in the sand filter was replaced with HS-200. This replacement resulted in decreased oil and heavy metals content and is now less than 1 ppm. They are saving $50 per day on bags. Cleanup of the RO membranes and ion exchange tanks plus regeneration or resins is now done every two to three weeks. They reduced the cleanup and regeneration costs by one half to one third. With the cost up to $10/cubic foot of resin for regeneration and all the disruptions associated with it, the use of HS-200 for water cleanup is extremely beneficial.

Industry Type: Metal Plating Plant, Wastewater

Pollutants: Heavy Metals, Oil, Calcium, Magnesium

Media Used: HS-200

Read More -

Economical Remediation Solution for Manufacturing Facility

A medium sized manufacturer located in western Michigan was visited by the local sanitary district inspectors. The purpose of the visit was to locate the source(s) of contamination that upset their biological treatment system. It was discovered that their compressor condensate contained approximately 35% by volume of free oil. Even though the amount of contaminated water was not enough to have caused the upset, it triggered enough concern that the inspector locked out the discharge source. The highly concentrated oily water was a significant cause of elevated levels of BOD, COD and oil and grease in the discharge water. The facility was advised to remediate the situation immediately or face a total shut down of their manufacturing.

The problem was quickly solved by placing HS-200 Condensate Remediation Paks at every compressor condensate discharge. The Paks were chosen for their ease of installation and low maintenance requirements.

Read More -

Meeting New York’s Stringent Water Regulations

A New York manufacturer of pharmaceutical products such as cream and ointments is required to clean equipment daily with soap and hot water. The wastewater is collected in a grease trap separator and then into a sump pit where a surface oil skimmer removes any floating oil and grease. This wastewater then passes through an oil magnet filter for discharge into the New York City sewer.

The emulsified oil phase consists of white petroleum, stearic acid, fatty acid stearates, fatty alcohols, mineral oils, oxyethylene ethers and stearates. The average concentration of emulsified oil is 5 – 400 PPM. Average daily discharge is 3,110 gallons. The New York City regulations stipulate a discharge level of no more than 50 PPM petroleum hydrocarbons which is a level frequently exceeded by the manufacturer.

This manufacturer needed a solution to sufficiently lower the chemical contamination in their water discharge. Two trains of filtration vessels were set up in parallel. The lead unit contains 350 lbs of HS-200 followed by 190 lbs of a blend of a bituminous and coconut shell activated carbon. Over 250,000 gallons of wastewater have already passed through the optimized system and test samples report no detection of hydrocarbons.

The company achieved these superb results by installing an $8,000 filtration system using organically modified media and activated carbon. This was an 80% savings over the $40,000 ultrafiltration system they had initially considered, thus lowering the company’s capitalization costs by at least $32,00 in one stroke. In addition, the filtration media is expected to have to be changed once a year.

Read More