Water Filtration Media

Treating Contaminated Water in Industrial Setting

Hydrosil works heavily with industrial water filtration. Industrial water filtration typically begins with removal of suspended solids with the use of a sand filter or bag filter. The next step toward clean water is removing harmful contaminants (volatile organic compounds, heavy metals, oil/grease, etc.). Hydrosil provides media to remove contaminants which affect product quality, state water discharge limits, and performance of industrial equipment.

Hydrosil has a wide range of filtration medias available to remove cationic and anionic species. Based on water analyses provided to Hydrosil—Hydrosil will deliver you the best filtration solution. To meet every pollutant problem Hydrosil manufactures customized blends. Contact us at [email protected] to obtain a sample for your treatability study today!

Hydrosil’s HS-100 is designed to remove ammonia in water. This product is commonly used in stormwater treatment and process water reuse.

HS-200

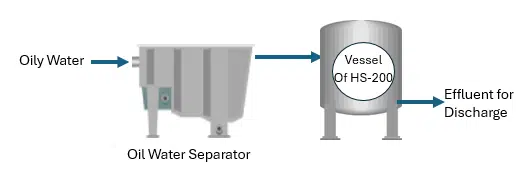

The HS-200 targets oils/grease, hydrocarbons, cations, non-aqueous phase liquids, and heavy metals.

This product is commonly used in dewatering sites, groundwater remediation, condensate treatment systems, process water reuse, pre and post industrial water treatment.

The HS-250 is a 50/50 blend of HS-200 and anthracite coal targeting heavy metals, oils, petrochemical compounds. This product is commonly used in dewatering sites, groundwater remediation, and stormwater.

HS-250-AC

The HS-250-AC targets a wide range of organics and inorganic compounds. Commonly used on BTEX, heavy metals, oils, semi-VOCs. The HS-250-AC is a 50/50 blend of HS-AC and HS-200.

The HS-250-ACR is a 50/50 blend of HS-200 and HS-ACR targeting heavy metals, oils, petrochemical compounds. This product is commonly used in dewatering sites, groundwater remediation, and stormwater.

The HS-250 is a 30/70 blend of HS-200 and anthracite coal targeting heavy metals, oils, petrochemical compounds. This product is commonly used in dewatering sites, groundwater remediation, and stormwater.

HS-275

The HS-275 is modified organoclay that targets low molecular weight hydrocarbons. This product is typically used in groundwater treatment for refineries.

HS-300

The HS-300 targets anionic compounds such as phosphates, nitrates, sulfates, cyanides. This product is commonly used in dewatering sites, groundwater remediation, and stormwater.

HS-350-AC

The HS-350-AC targets a wide range of organics and inorganic compounds. Commonly used on anionic compounds such as phosphates, nitrates, sulfates and large organic compounds. The HS-350-AC is a 50/50 blend of HS-AC and HS-300.

The HS-AC is granular activated carbon (GAC) produced from coconut shells. The product targets inorganic and organic compounds in a wide range of applications.

HS-ACR

The HS-ACR is reactivated granular activated carbon (GAC) produced from coconut shells. The product targets inorganic and organic compounds in a wide range of applications.

The HS-ACC is granular activated carbon (GAC) produced from coal. The product targets inorganic and organic compounds in a wide range of applications. The HS-ACC has micro and macro pore structure to adsorb a wide range low and high molecular weight hydrocarbons.

Hydrosil’s HS-AS is designed for arsenic removal for water treatment. The HS-AS is commonly used in pump and treat systems and polishing water in industrial settings.

Hydrosil’s HS-F is designed for fluoride removal for water treatment. This activated alumina is an adsorbent of metals as well as fluoride.

The HS-MT is extremely effective at removing dissolved metals. Common metals found in water include nickel, cadmium, zinc, chromium, and thallium. This product is typically used in groundwater and surface water treatment.

Common Treatment System Design:

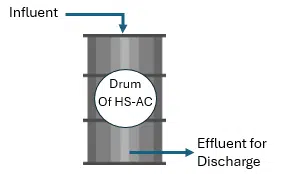

Free Standing Mode: Used on its own, Hydrosil’s media can be loaded in drums or large vessels for use as an efficient bed filtration medium. Other applications include tank cleaning, oil spill mitigation, stormwater run-off, pond clean-up, excavation and dewatering, manufacturing/chemical processes, and lining/capping projects.

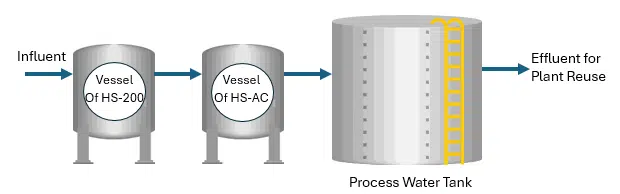

Pre-Treatment Mode: Media is used upstream to enhance the performance and extend the useful life of other filtration processes and media such as reverse osmosis (RO), granular activated carbon, activated alumina, and resins. Fouling of RO systems is not uncommon due to the presence of silica, oil, and heavy metals.

Post-Treatment Mode: Media is utilized downstream of an oil-water separator or coalesce filter, has the ability to act as an effective cleaning and polishing agent.

Give us a call today at 847.844.0680. Let’s discuss your unique application needs.

- Activated Carbon

- Organoclay

- Activated Alumina

Case Studies:

RO Membrane Protection

PFAS/PFOA Limits

Economical Remediation for Manufacturing Facility

Arsenic Removal in Groundwater from Landfill

Water Filtration and Remediation

Water Treatment

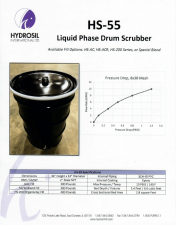

HS-55 Water Treatment

HS-350-AC