Liquid Phase, Coconut Shell Reactivated Carbon

What is HS-ACR

Hydrosil’s HS-ACR is a reactivated granular activated carbon (GAC) manufactured via high temperature steam activation from selected grades of coconut shell. Hydrosil’s HS-ACR is designed for liquid phase applications. The HS-ACR is high quality carbon with extraordinary surface area, fine pore structure, high density, and superior hardness. Hydrosil’s HS-ACR for treating liquid phase uses macro and micro pore adsorption to remove contaminants.

Where is HS-ACR Used

HS-ACR is commonly used in oil and gas refineries, and industrial pollution control. Industrial projects that use HS-ACR include groundwater treatment, stormwater run-off treatment, and removal of dissolved organics.

What is Reactivated Carbon

Reactivated carbon is a cost-effective alternative to virgin activated carbon. After the activated carbon is spent, the adsorbed organic compounds are destroyed via thermal treatment allowing the activated carbon to be used again. To reactivate carbon, the activated carbon is heated to high temperatures near 900°C which allows the organics that were adsorbed to be released from the pore structure. Once the organics are removed from the activated carbon pore structure the carbon is ready to be used again. The regeneration of activated carbon does result in a small loss of the activated carbons’ adsorption capacity.

What is Activated Carbon

Activated carbon commonly referred to as activated charcoal is a highly porous material used to remove pollutants from contaminated liquid and gas streams. Activated carbon is derived from a variety of raw materials such as coconut, wood, coal (bituminous, anthracite, sub-bituminous, and lignite), peat, and bamboo. Each raw material has unique properties which effect the resulting pore structure, carbon content, and ash content, which are important characteristics when removing a contaminant of concern. The material is used in remediation, medical, and industrial applications where adsorption is required. Activated carbon has strong physical adsorption properties known as London Dispersion Forces which is a Van der Waals Force. The attraction between the activated carbon and the pollutant are highly dependent on the vapor pressure of the adsorbing molecules. Activated carbon is often altered or impregnated by chemicals to enhance the surface area of the carbon. When the carbon is chemically altered the bonds are much stronger than London Dispersion Forces. Chemicals often impregnated on activated carbon include potassium hydroxide, phosphoric acid, or sulfur. With the addition of chemicals the activated carbon will have an affinity for select compounds such acidic or basic pollutants.

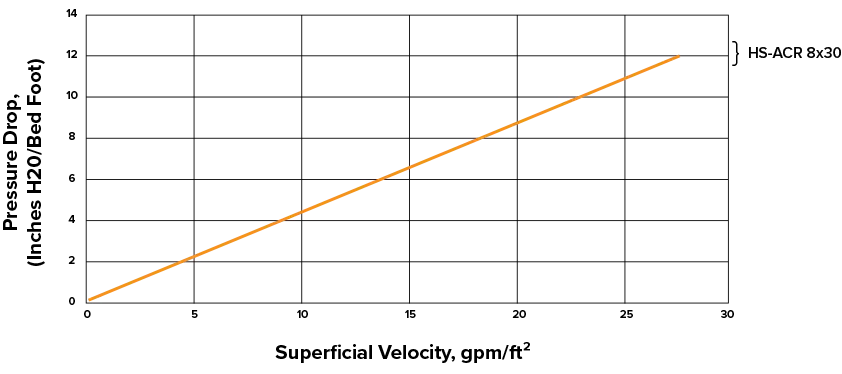

HS-ACR Pressure Drop

TYPICAL PHYSICAL PROPERTIES

| Property: | Value: |

| Iodine Number, | 1000 |

| Apparent Density, lb/ft 3 | 29-31 |

| U.S. Standard Sieve Size (Mesh Size), 90% min | 8 x 30 |

| Hardness, Min. (ASTM D-3802) | 95 |

| Total Surface Area (BET), m 2 /gm | 1100 |

- Activated Carbon

- Organoclay

- Activated Alumina

Common Applications:

- BTEX

- Polychloro-biphenyl (PCB)

- 1,2-dichloroethane (DCE)

- Chlorine

- Pesticides

- Polynuclear-aromatic-hydrocarbons (PNA)

- Trichloroethylene (TCE)