Vapor Phase, Potassium Permanganate

Hydrosil’s HS-600 uses reactive chemistry to oxidize various pollutants. The HS-600 is zeolite impregnated with 6% potassium permanganate (KMnO4). Its’ high impregnated level of KMnO4 and insignificant dusting attributes make it an ideal media for gas phase filtration. The HS-600 is designed for removing acid gases, aldehydes, amines, and various hazardous air pollutants. The media is typically used in the following industries:

- Fresh fruit and vegetable transportation

- Refineries

- Pulp and paper mills

- Ground water remediation

- Wastewater treatment

The media is loaded in tanks, exhaust systems, soil vapor extraction (SVE) systems, air filtration trays and modules. To see if the HS-600 removes a specific pollutant please see our Air Pollutants page, or contact a representative today.

What’s the Difference Between HS-600 and HS-400?

HS-600 is zeolite impregnated media and HS-400 is activated alumina impregnated media. Both medias are impregnated with potassium permanganate (KMnO4) which oxidizes acid gases and odors. The HS-600 is a harder material than the HS-400; Therefore, the HS-600 will result in insignificant dusting. Depending on the application, Hydrosil will suggest either the HS-600 or HS-400.

What is Potassium Permanganate?

Potassium permanganate (chemical formula KMnO4) similar to sodium permanganate is a crystalline purple solid that dissolves in water. Potassium permanganate uses include: medical use, water treatment, industrial use, analytical use, fruit preservation, and manufactured goods such as fire starters. Through oxidation-reduction (redox) reactions, KMnO4 is used in vapor control to remove harmful gases such as DCE, TCE, and styrene. Hydrosil often works with industry users that are targeting vinyl chloride (VC) monomer.

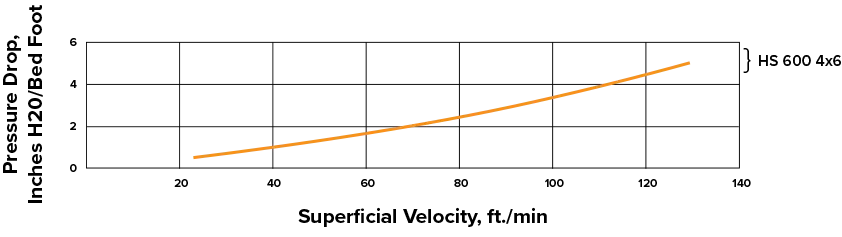

HS600 Media Pressure Drop

HS600 TYPICAL PHYSICAL PROPERTIES

| Property: | Value: |

| Potassium permanganate impregnated, % wt. min. | 6.0 |

| Bulk Density, lb/ft 3 | 60-62 |

| Hardness, Min. (ASTM D-3802) | 95.0 |

| Particle Size | 4 x 6 |

| Optimal Relative Humidity Range for Operating | >20% |

Common Applications:

- 1,2-dichloroethane (DCE)

- Trichloroethylene (TCE)

- Hydrogen Sulfide

- Mercaptans

- Acid gases

- Vinyl chloride (VC)

- Common Odors

- Aldehydes

- Ethylene

- Amines

- Chlorinated Solvents